Machining is a sector of never-ending demand and an ever-growing market, with its estimated market to be around $415 billion by 2022. The market has been revolutionized by the Computer Numerically Controlled, or CNC machines. CNC turning machines have the most widespread utility in the machine manufacturing sector, with the ability to shape equipment of Automotive, Aerospace, Energy, Agricultural and Mechanical Industries, among others.

CNC turning machines use a variety of complex and fine precision techniques to make a shining piece of equipment almost out of scrap. All these figures force one to ponder upon the question of how does a CNC turning machine works?

How Does CNC Turning Machine Works?

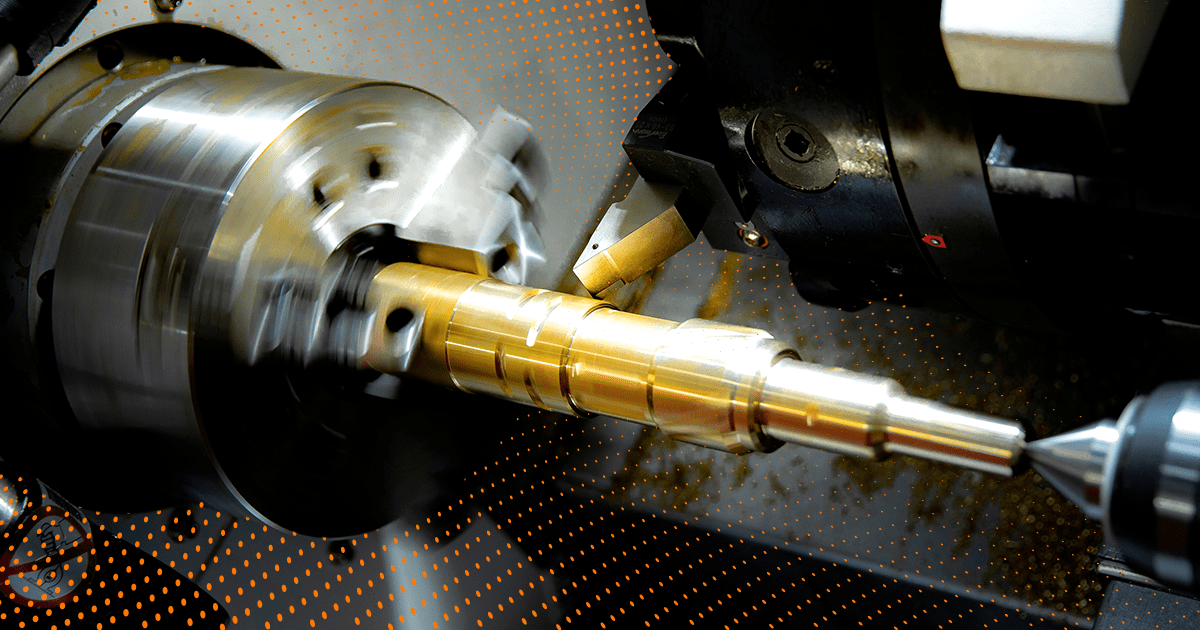

CNC turning machines work on the method of “subtractive machining,” meaning that material is removed from the original matter to obtain a final piece.

The Mechanical Body of a CNC turning machine consists of Chuck (specialized clamp), which tightly holds the material under process. Then there is a wide array of drilling, scrapping, and filling tolls loaded on a Turret. By the action of a computer-generated G-CODE, chuck is made to turn, and a specified tool on the turret is used to shape the final product.

CNC turning machines usually are associated with manufacturing cylindrical and round objects out of raw materials ranging from Metals (aluminum platinum), Alloys( steel), and even Wood. However, for every different type of raw material, some of the settings of the apparatus have to be adjusted, but the general working procedure remains the same.

There are two broad categories of CNC turning machines, Horizontal Turning Machines and Vertical Turning Machines; both have almost similar working; however, vertical turning machines do use the force of gravity in their working and are far less common than their horizontal sibling.

In General, CNC turning machines can perform many processes to formulate a final product; some of the processes are;

- Drilling: making round holes for screws and bolts.

- Grooving: cutting small gaps and cavities in the workpiece.

- Parting: separating different workpieces from one another.

- Threading: making cavities that can be screwed together

- Taper turning: drilling a hole of gradually increasing/decreasing diameter

These basic functions, amongst others, make it possible to convert a lackluster bar of metal into an exhaust pipe for your car.

Use of Computers in CNC Turning Machines

- CNC machines were previously designed to work manually, but with automation, they’ve gained the ability to produce better quality, highly precise, and that too in a cost-effective and less time-consuming manner.

- A Designing expert using the help of software such as AUTOCAD and Solid Works creates a design of a final product, and then the workpiece goes through a series of controlled processing in a CNC machine to achieve the desired product.

- CAD, GAD, and GAM are the basic programs used in generating the G-CODES; the codes and CNC can also be programmed to run via AI, allowing minimal human involvement and maximum output

- Operating the CNC Machines is no child’s play, and you need at least 3 months to learn how to maneuver this machine.

Top 5 Advantages of CNC Turning Machines

CNC machines have many upsides that make them the flag bearer of the machining industry.

- Precision: CNC turning machines can be twice as precise as the diameter of our hair; that is some precision, isn’t it? CNC machine has another ace of spades up their sleeves; they can make more detailed products than 3D printers.

- Uniformity: The use of computerized code makes sure that you’ll always get the same final product; manual errors are minimized.

- Labour: The CNC machine needs no breaks for a meal, and it never gets tired; it can virtually work 24/7 decreasing the need for labor and saving valuable bucks for you. Only a few experts are needed to run the operations.

- High Speed and Efficiency: The CNC turning services are much more speedy, allowing us to create a lot more products and reach our targets quicker.

- Wide Range of Raw Materials: Whilst 3-D printing is very limited in the type of raw materials we can use, CNC can work on a wide range of workpieces, from wood and plastic to metals and alloys.

CNC Turning Machines’ Comparison

- CNC turning machine isn’t the only CNC service Available; CNC milling is also one of the most popular modes of CNC machining.

- CNC turning is mostly preferred over other machines for round or cylindrical products, whilst the CNC milling machines are more suited to form rectangular-shaped products.

- CNC turning services are much faster and more affordable, but their diversity in product formation is below par in comparison with milling machines. CNC milling machines are known to conserve raw material as their level of subtraction is lesser.

- In some cases, both Milling and Turning machines are used to create a single product.

CNC Turning Service in Houston

CNC turning machines work at different axis; the most basic turning machines work at 2 axes, whilst at our CNC turning services, we’ve got a four-axis rotating apparatus that allows you to create the sleekest of all products.

Our team is composed of CNC experts with decades of experience under their belts. These professionals have been making products for

- Automotive Industry: Door equipment, designing, and exhaust systems

- Agricultural Sector: Harvesting machinery’s parts

- Aerospace: machinery used inside rockets and spaceships and in airplanes.

- Energy and Mechanical Industries: Small equipment and frames of PV cells.

However, the scope of CNC Turning services in Houston, Texas, goes beyond these fields.

Conclusion

Machining is a never-ending field, and with advancements in technology and the need for fast-paced production, the usability of CNC turning services will only increase.

CNC turning machines have the capability to quite literally shape different industrial and commercial sectors, and this is sufficient to show their worth.

We hope to play our part in this ever-growing global village by providing precise, economically feasible, and high-quality CNC turning services to our customers. Don’t forget to visit our website for more details.