Capital intensiveness has reached a point that by the end of 2025, it is expected that CNC machining will be a 100 billion dollar market. Can you imagine? But yeah, that’s what industries and manufacturing businesses are relying on.

If you are new to the CNC machine concept then you have landed here right, let dive in to know more!

So, What Is A CNC Machine?

Times have gone by where manual help would be required to set up the machines for production matters. CNC, computer numerical control, the machine is used for manufacturing processes that help in controlling a wide range of complex tasks.

It won’t be wrong saying that CNC machine has taken the manufacturing world by storm. Its multipurpose ability, versatility, and other extensive benefits have takeover the manual operations.

CNC Machine; Programming

Shifting to CNC machines doesn’t eliminate the need for human input to the fullest. In fact, manual coding is required to set the CNC machine programming in order for it to function properly.

As simple as that, there is no CNC machining without programming.

The language for CNC machine programming is referred to as G-code.

Usually, most manufacturing codes serve a single or at max two functions. However, G-code serves a greater range of complex behaviors like speed, coordination rate, and feed rate.

Once the code has been fed to the CNC machine, there is little to no need for humanly processes afterward. However, the codes once fed at not permanent. They can be revised throughout and hence allow the changes to be made at any point in time.

What Is A CNC Machine Used For?

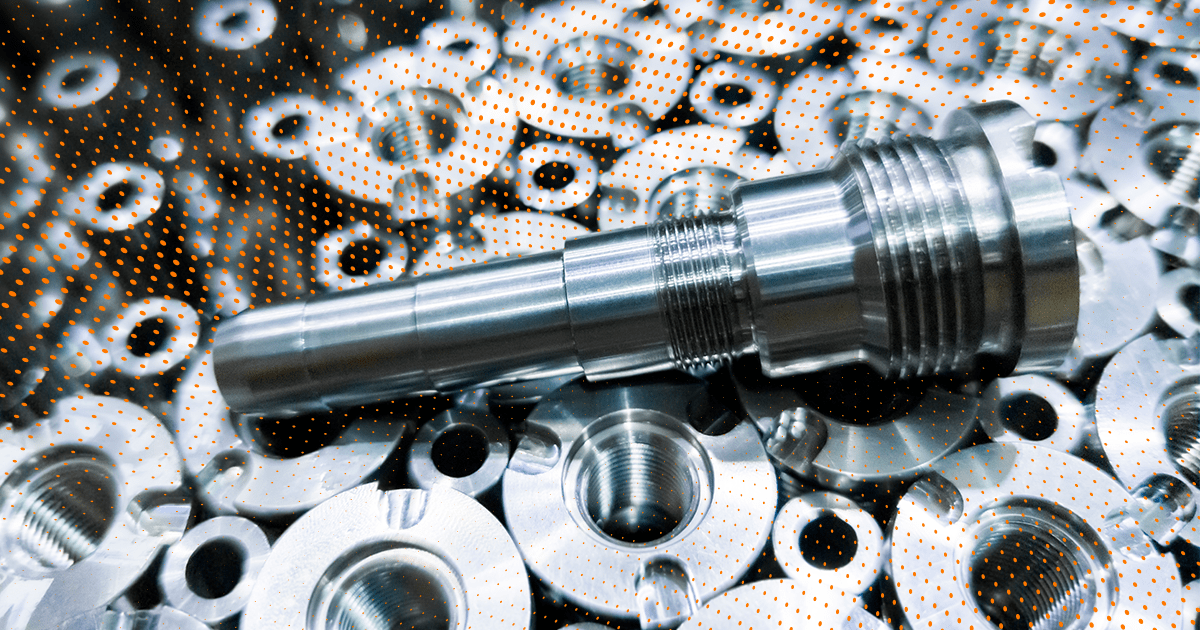

CNC machines can be used to produce a countless variety of goods and that too quickly and efficiently.

So, most commonly, it is used in metal and plastic manufacturing to cut out the metals pieces for hardware products. In addition, CNC machining facilitates the manufacturing processes like wood routers, laser cutters, foam cutters, glass cutters, and whatnot.

All in all, CNC machining quickens the process of complicated cuts and helps you get done with the work in a matter of minutes.

But, it all comes down to the right coding of the programs inside the CNC machines.

Different CNC machine types

There are many different types of CNC machines. Some of them are as follows:

1. CNC Lathe Machine

CNC lathe machining is very common and popularly used for its fast, efficient, and accurate functioning. It consists of a lathe at the center that allows to management and transfer of the material programmatically to the computer.

2. CNC Drilling Machine

It is often being used for mass production. It has a multi-purpose functioning machining center that can be mingled and twisted.

3. CNC Laser Cutting Machine

As the name implies, the laser is used to cut the materials instead of the plasma torch. The usage of the laser allows for greater accuracy to be achieved.

In A Nutshell

Understanding CNC machining at first might seem a complicated task in itself. However, once you get the hand of the right type of CNC machine, and its programming you will realize the convenience it has brought.

If you are in search of a precision CNC machining facility in Houston Tx, then look no further since Bravo machining has got you covered!