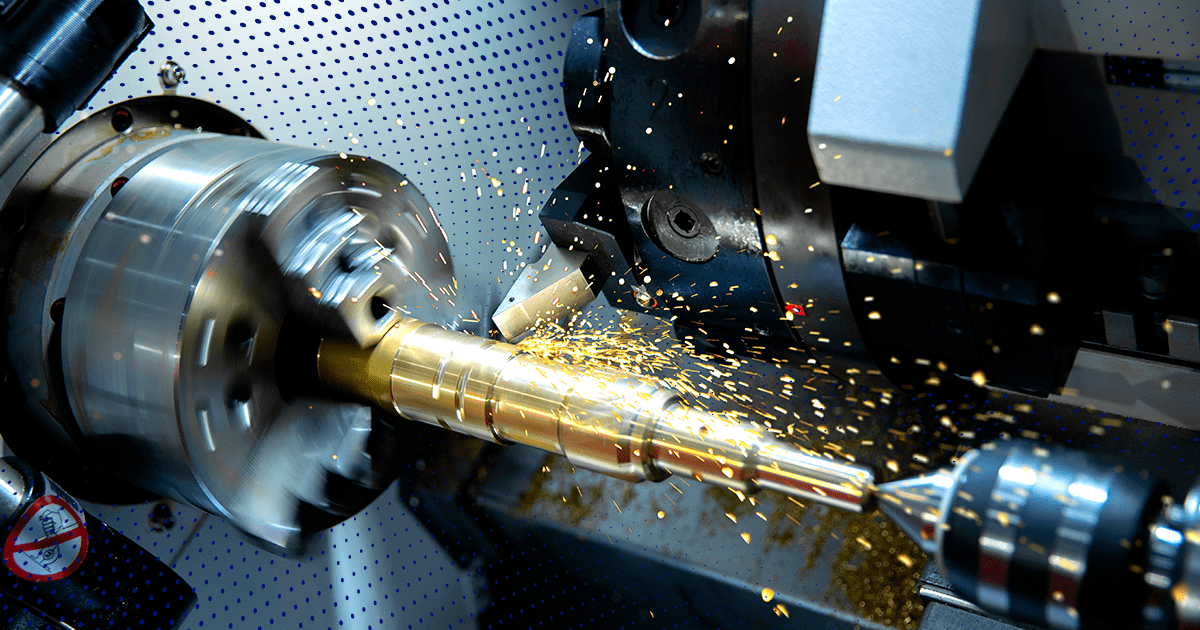

Whether you are a small-scale manufacturer or a large corporation, CNC (Computer Numerical Control) Machining is now being used worldwide in different industries.

Many high-end industries and manufacturing companies are switching to CNC machining due to its efficiency and effectiveness.

It’s always good to know what you’re working with. There are several advantages of CNC machining over manual machining and vice versa.

If you’re looking for an effective and efficient process for your next project, below are the 13 advantages of CNC versus manual machining.

Top 13 Most Efficient Advantages of CNC Machining Vs. Manual Machining

The benefits of CNC machining are ease of use, consistency, precision, speed, and cost.

1. CNC Machining Can Increase Productivity

CNC machines can produce more parts in a shorter time than manual machining. In addition, the parts’ accuracy is much greater than that of hand-machined parts.

2. CNC Machining Can Be Used for a Variety of Applications

Because of their versatility and flexibility, CNC machines can be used for various applications, including but not limited to metalworking, plastic working, and woodworking.

They can also be used in other industries such as aerospace, medical equipment, and aerospace applications.

3. Building Your Machine Increases Cost

The cost of building your machine is much higher than buying one from an established manufacturer who has already created all the components needed for successful operation.

All you need do is assemble them together at home with some help from an expert if necessary, thereby saving money on buying ready-made machines that may have fewer capabilities than you need in your business.

4. Easy Tolerances

Manual machining requires tight control over every movement made by your machine tool (drill press, lathe, milling machine).

This makes it difficult to produce parts with consistent tolerances – not only because the human error may creep in during setup, but also because different materials have different properties and require different setups for optimal results.

With CNC code controlling your machine tools, this is no longer an issue – all parts are consistent regardless of material type or geometry!

5. Faster Setup Time

Manual machining requires that you measure and set up each tool path by hand. This can take hours per part if you’re making small parts, but even minutes if you’re making hundreds or thousands.

The time savings are especially evident when building your machine because it’s one less step that needs to be done manually – everything can be automated using CNC code.

6. Repeatability

CNC machines allow for repeatability when producing an identical part or piece of inventory because they have been programmed with exact specifications on how they should perform their functions when creating your product or part(s).

This ensures that every piece you create is identical and will perform exactly as expected every time it is used by its users (customers).

7. Unlimited Production Capabilities

The main advantage of CNC machining is its ability to produce multiple parts at once. Manual machining can only make one part at a time, which takes longer.

This means that CNC machines are better suited for mass production than manual machines, as they can produce large volumes of parts in a shorter time.

8. Fewer Errors amongst Parts

Another advantage of CNC machining is that there are fewer errors in the finished product because each machine has been programmed according to specific requirements set by customers.

Each machine has been programmed with the correct tool orientation, cutting speed, feed rate, etc., so it cuts only what it needs to slice and nothing else.

This prevents over-cutting or under-cutting of parts that may occur during manual machining.

9. Material Diversity

One of the main advantages of CNC machining over manual machining is the variety of materials that can be processed. Manual machining has a minimal range of materials that can be processed, while CNC has no limitations.

This means you can use your machine to process various materials, including metal, plastic, wood, and composite materials like carbon fiber.

10. Increased Tool Life

CNC machining also offers more tool life than manual machining because machines use tools specifically designed for each application.

These tools are usually made from high-quality steel or carbide, which means they last much longer than typical manual tools made from less durable materials like HSS or high-speed steel (HSS).

In addition, most CNC machines have automatic tool changers, allowing you to switch between different tools without having to stop working on your project or change any settings on your machine.

11. Cost-Effective in High Production Volumes

CNC machining is cost-effective when it comes to high production volumes. This allows you to get more parts simultaneously than manual machines. This can reduce your overall cost per part and save money on labor costs.

12. Ability to Do 3D Projects Rather Than 2D Projects

CNC machining can also be used for complex projects instead of simple 2D projects. You can use this technique to make complex shapes or even create 3D models from scratch without any need for drawing plans or blueprints first.

CNC machines are also capable of performing various operations at once, rather than performing them one after another like manual machines do.

This makes the process quicker and more efficient than manual methods, requiring you to perform each operation separately before moving on to the next.

13. Great for Complex Parts That Require Specialized Tooling and Fixtures

CNC machines can be programmed to produce complex parts that may require specialized tooling and fixtures.

Manual machines cannot produce similar types of parts because they cannot hold multiple tools at once without human assistance.

Summing Up!

CNC is a more productive way to make better-quality products in less time. Manual machining has advantages, such as more significant piece variability and lower setup costs.

But for most industrial applications, CNC technology is the easy pick over manual machining. And you couldn’t ask for better proof than a look at these twelve top advantages of CNC machining.

US Machine Shop is one of the best CNC machining companies in Houston, Texas. As a leading provider of CNC machine parts, they are trying to pay more attention to their customer’s needs and always ensure that they provide them with the most reliable and cost-effective solutions.