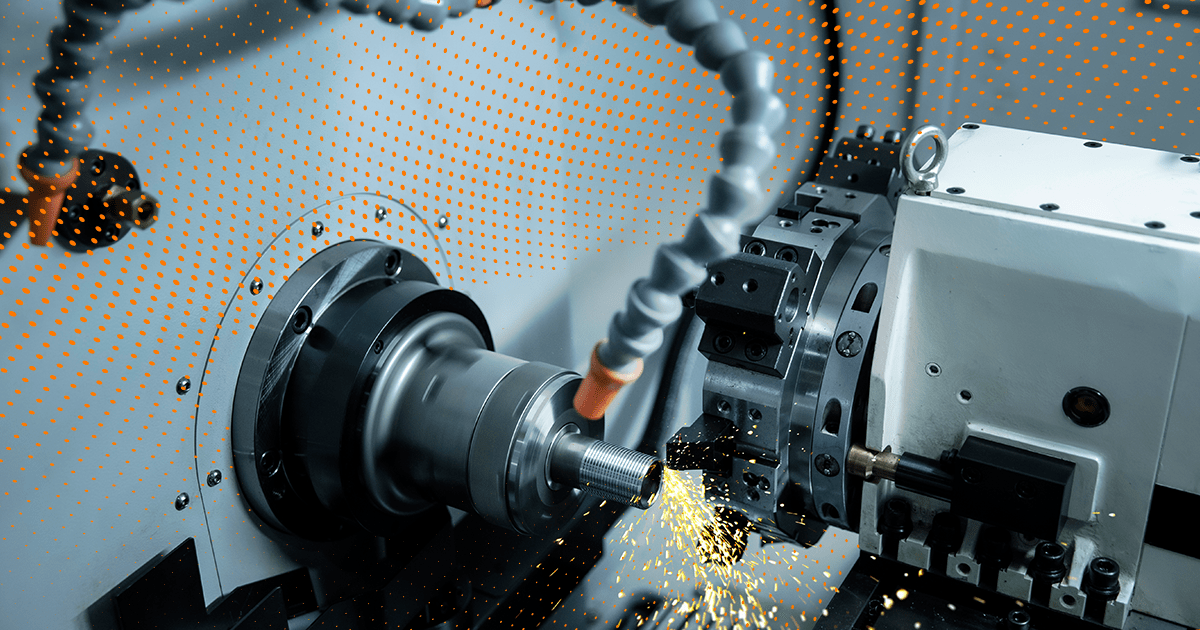

CNC manufacturing companies have a special place in the hearts of many engineers and project managers. This is good because CNC machines are explicitly designed to cut materials into shapes according to specified CAD drawings.

There’s an endless amount of industries served by CNC machining, and within those industries, you have a wide range of applications.

It can be challenging to know where to start, whether it be serving your first manufacturing customer or what parts you should be capable of producing.

In this article, we’ll go over the top 5 industries served by CNC machining and what parts you need to build, so you have a better understanding of how to jumpstart your business.

Top 5 Most Precisely Manufactured Industries Served By CNC Manufacturing

As you’re well aware, automotive, aerospace, marine, and medical industries require state-of-the-art components that must be manufactured precisely and efficiently.

-

Automotive Industry

CNC machining is a prevalent method of manufacturing in the automotive industry. Almost every car on the road today has been manufactured using CNC machines. This includes body panels, engines, transmissions, wheels, and other parts.

The high level of precision that CNC machines offer allows for greater quality control and consistency. However, it is essential to note that not all cars use CNC machining for all parts.

For example, some cars still have manual transmission options available to consumers even though most vehicles use automatic transmissions because they are much more reliable and easy to assemble.

Moreover, the automotive industry has a long history of using CNC machines to produce parts, and this trend will continue in the future. Many different types of vehicles and components are made using CNC machines. Some examples include:

- Car engines

- Tires

- Brake pads

- Seatbelts

This vast market drives demand for CNC manufacturing and provides a wide array of opportunities for companies specializing in this field.

CNC manufacturers are responsible for many parts used in cars, including:

- Transmissions

- Steering mechanisms

- Motor mounts

- Cylinder heads

- Exhaust manifolds

-

Medical Device Manufacturing Industry

The medical device industry is one of the most prominent industries that use CNC machining for their manufacturing needs. From surgical tools to prosthetics, the medical device industry has a wide variety of products that must be manufactured precisely.

This industry requires complex parts that may need several manufacturing processes to achieve the desired level of precision. CNC machining allows companies to produce accurate details at high volumes, which reduces costs and improves efficiency.

The reason why this industry is overgrowing is that there are more and more people who need medical devices to help them live their lives better. The more devices required, the more jobs are created in this field, making it an ideal place for any person to work.

-

Aerospace Manufacturing Industry

Aerospace manufacturing is the process of building aircraft and related parts. It is subdivided into airframe, engine, and component manufacturers. The aerospace industry is a global enterprise, with the U.S., Western Europe, Japan, and China significant players in this market.

The aerospace industry has been one of the fastest-growing sectors of the global economy over the last century. It has been driven by technological advances that have allowed humans to travel at faster speeds, reach higher altitudes and set foot on other planets in our solar system.

As technology advances, new opportunities emerge for companies involved in this field.

With so many different types of aircraft being manufactured today, these crafts must have durable and reliable parts.

This means they need to be made with precision tools like CNC machining if they’re ever going to achieve their full potential as a vehicle for transporting people or cargo around the world.

Aerospace companies rely on CNC machining services to produce parts for military aircraft to commercial passenger jets.

-

Electronics Manufacturers Industry

Electronics manufacturers use CNC machining to produce a variety of products. These include electronic components, circuit boards, and microelectronic devices. The electronics industry is one of the world’s most significant users of CNC machining services.

The electronics manufacturing industry is divided into discrete electronics and semiconductor devices. Discrete electronics are those that are not made on a single chip. Examples include radios, televisions, and computers.

Semiconductor devices are made on a single chip through doping and etching. Examples include microprocessors, transistors, and diodes.

The major markets for CNC machining in the electronics manufacturing industry include:

Automotive Electronics

This includes almost all types of automotive electronics used in today’s vehicles, including engine control units (ECUs), powertrain control modules (PCMs), navigation systems, infotainment systems, and instrument clusters.

Consumer Electronics

Consumer electronics include any device used by consumers that requires some electrical circuitry, such as televisions, DVD players, digital cameras, etc.

-

Architecture Models and Prototypes Industry

The Architecture Models and Prototypes Industry is a top player in the CNC manufacturing industry.

CNC machining is used in this industry to create architectural models, prototypes, and other small-scale models. It’s also used for making tooling, fixtures, and jigs.

In addition to architecture models and prototypes, this industry also includes producing custom parts and components for commercial aircraft manufacturers.

The main products produced by companies in this industry are:

- Architectural models

- Prototype parts

- CNC milling machines

- CNC lathes

Moreover, the architecture models and prototypes industry has grown over the years as more architects have become interested in using 3D printing technology for their projects.

As a result, there has been an increased demand for equipment like CNC machining centres from companies like Shapeways Inc., which manufactures 3D printed products for architects and designers worldwide.

Summing Up!

When something goes wrong, it is not just the equipment and machinery that can be impacted. Often, suppliers can find themselves in major trouble if there is a defect or mishap in the manufacturing or distribution process.

This is why companies must ensure they buy from reputable vendors and businesses. However, finding the one shop that sells a suitable machine can be a hassle; finding several such shops can be nearly impossible.

That’s where U.S. Machine Shop comes in. U.S. Machine Shop provides an index of sellers who sell the products you need and have been thoroughly vetted to ensure they are trustworthy.

Using this service, any business can easily find the right vendor for their needs, regardless of industry or market.