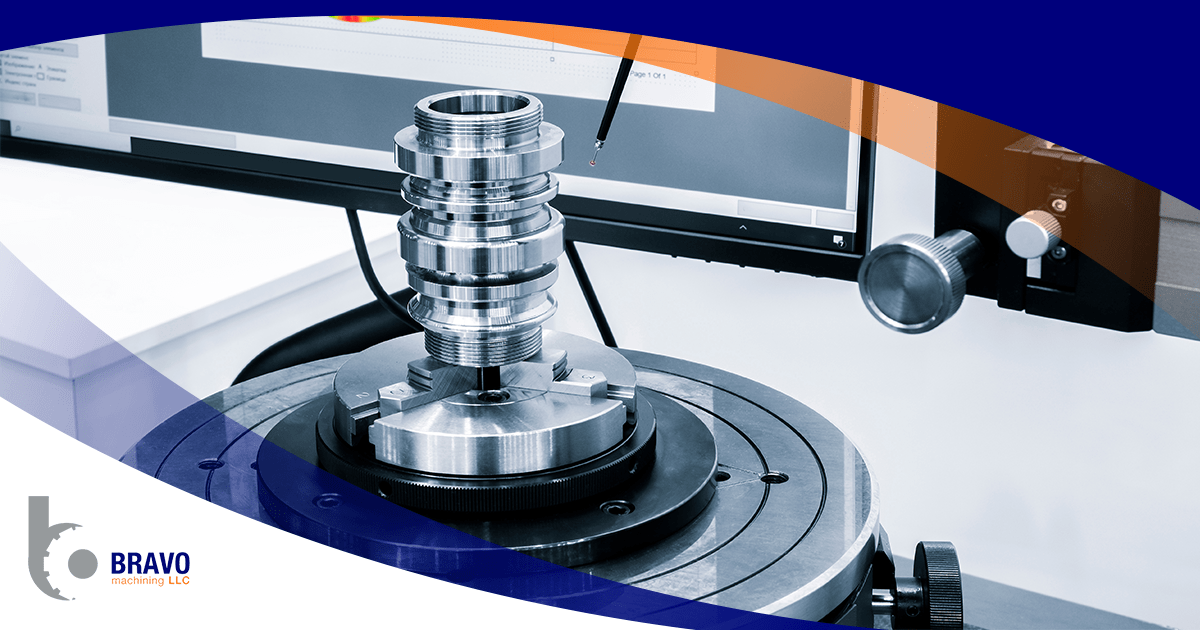

Precision measurement is a critical aspect of CNC machining. Ensuring that parts are manufactured to exact specifications is essential for quality control and overall product performance. In this blog post, we will delve into the importance of precision measurement in CNC machining and the techniques used to achieve it.

Importance of Precision Measurement:

Precision measurement ensures that each machined part meets the required specifications and tolerances. This is crucial for maintaining product quality, performance, and reliability. In industries such as aerospace and medical, even the slightest deviation from specifications can have significant consequences.

Techniques for Precision Measurement:

- Coordinate Measuring Machines (CMM): CMMs are widely used in CNC machining for precise measurement of part dimensions. These machines use a probing system to measure the geometry of objects accurately. They are capable of measuring complex shapes and surfaces, making them ideal for quality control.

- Laser Scanning: Laser scanning is a non-contact measurement technique that uses laser beams to capture the shape and dimensions of a part. This method is highly accurate and can quickly measure complex geometries. It is particularly useful for inspecting parts with intricate details.

- Optical Comparators: Optical comparators project a magnified image of a part onto a screen, allowing for precise measurement of its dimensions. This technique is useful for inspecting small parts and verifying that they meet the required tolerances.

- Micrometers and Calipers: Traditional measurement tools like micrometers and calipers are still widely used in CNC machining. These tools provide highly accurate measurements and are essential for verifying part dimensions during and after the machining process.

Conclusion:

Precision measurement is a cornerstone of CNC machining, ensuring that parts meet the highest standards of quality and performance. The use of advanced measurement techniques like CMMs, laser scanning, and optical comparators, combined with traditional tools, enables manufacturers to achieve unparalleled accuracy. As technology evolves, precision measurement techniques will continue to advance, further enhancing the capabilities of CNC machining.