If you have ever wondered how custom CNC machining works? You are likely to wonder whether this is something you will be able to do yourself or whether you need particularly good equipment to achieve the same results as professionals have achieved with theirs.

CNC machining has been an important technology in the engineering industry for a long time. CNC machines are found in factories, workshops, and laboratories worldwide. Although their primary role is cutting, many firms use them for other purposes.

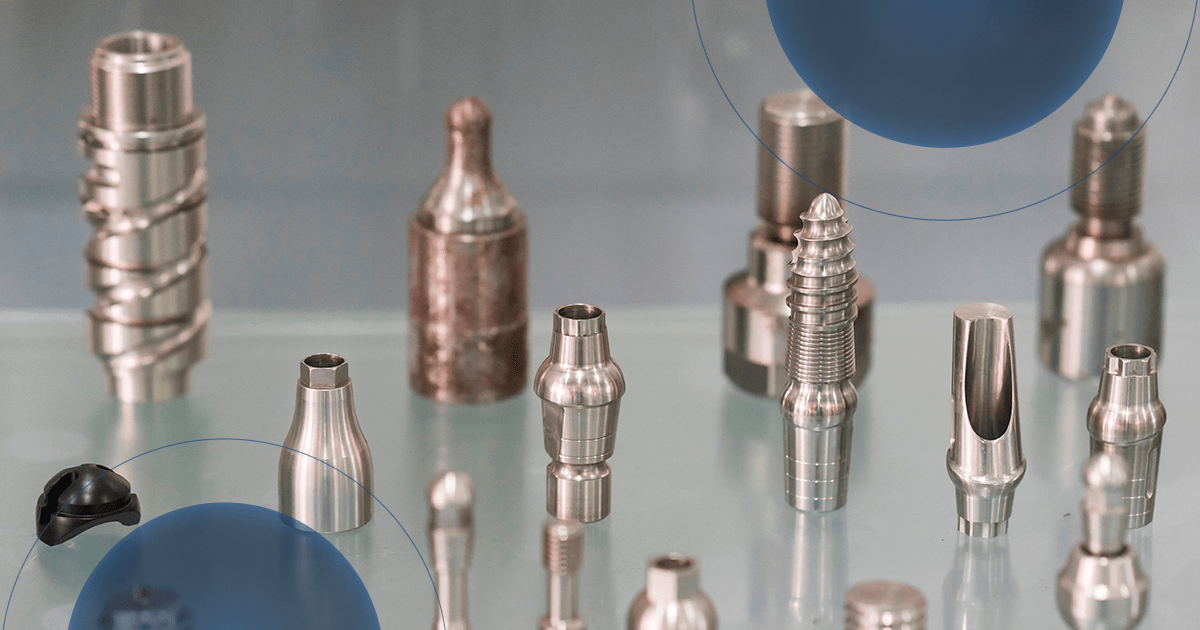

This includes specialized parts for air conditioning equipment and heat exchangers, optical instruments, medical devices and parts, electronic assemblies, and many others.

How did custom CNC machining work? In this article, we will explore the concept of custom CNC machining. Many aspects need to be dealt with before we start working, and we will touch upon them.

What is CNC Machining?

Custom CNC machining is a process that involves the use of computer numerical control to create custom parts and components from a variety of materials. Custom CNC machining is an efficient and accurate way to produce parts and components with high precision.

Custom CNC machining can be used to create parts and components with complex geometries and intricate detail. Custom CNC machining is a versatile manufacturing process that can create parts and components for various applications.

The benefits of custom CNC machining include the ability to create parts and components with a high degree of precision, the ability to create complex geometries and intricate detail, and the versatility to create parts and components for a wide range of applications.

The limitations of custom CNC machining include the need for skilled operators, expensive equipment, and the potential for scrap and waste. Custom CNC machining can be a costly manufacturing process, but the benefits often outweigh the costs.

What distinguishes CNC machining from other techniques like 3D printing? The final machined component is created through a subtractive manufacturing method in which the machining tool eliminates pieces from the workpiece. A 3D printing technique, on the other hand, employs an additive manufacturing process in which the printing device assembles layers of material to produce the final object.

The ability to generate highly precise and accurately engineered components makes the custom CNC process special. In a similar line, it is a sought-after practice in the industrial sector since it is economical. But one major problem is that it can’t handle intricate designs.

Which Things can CNC machines Make?

No restrictions appear to apply to CNC machining. It is appropriate for various materials, including metals, polymers, foam, composites, and wood.

3-axis milling machines can produce the most fundamental geometric shapes. Multi-axis milling centers are provided for more complex items.

This increases flexibility while also increasing expense. Even though CNC is far faster, hand machining has a position in the business. Particularly useful for low-volume fast prototyping.

A 5-axis CNC milling center, for example, can be of assistance. While a 3-axis machine has three linear axes of movement, a 5-axis machine may also rotate the cutting head and the machine bed.

However, CNC machining remains dominant in the market when great accuracy is required. This is why it is used by so many different sectors, including:

- Aerospace

- Electrical

- Defense

- Mining

- Machines used in industry

- Food and beverages

- Clothing

- Automotive

- Product design

Types of CNC Machines

There are Multiple types of CNC Machining which are versatile and task-oriented according to their manufacturing process. Here we are going to discuss a few of them;

-

Plasma-Cutting CNC Devices

CNC plasma cutting machines are used to cut materials. But unlike its milling rivals, they perform this task using a powerful plasma torch with a temperature range of up to 50,000 degrees Fahrenheit and can pierce difficult materials like metal!

-

Milling Equipment CNC Machine

Multi-point rotary cutting tools are moved and operated by computerized controls during the machining process known as CNC milling. To obtain the correct form and size, the tools steadily remove extra material as they rotate and travel across the workpiece’s surface.

Four separate steps can be distinguished in the CNC milling process:

- Engineers develop the needed item using a CAD model in 2D or 3D.

- Conversion of a CAD model to a CNC program: the design is exported into a compatible file format and changed using CAM software into machine instructions.

- Setting up a CNC milling machine: The operator gets everything ready for the machine and the workpiece.

- Execution of the milling operation: The machine operator launches the machining program.

We proudly offer high-precision CNC milling capabilities in 3 and 5 axes here at US Machine Shop. While 5-axis CNC milling is typically better suited to more complex geometries, 3-axis CNC milling is frequently the best choice for creating simpler parts. Usually, it is finished in a single step.

-

CNC Lathe Apparatus

Contrary to CNC milling, which involves moving the cutting tools to remove material, CNC turning involves rotating the material as it is being cut. The central lathe of CNC lathe machines manipulates and moves the material into the predetermined location using computer programming.

How Custom CNC Machining Work?

The field of engineering has seen great advancements in custom CNC machining. Punched tape cards were once often utilized in CNC machine shops.

Today’s CNC manufacturers employ computer-controlled machinery to carry out a variety of CNC machining operations, such as cutting, sawing, broaching, lapping, honing, and drilling, on a workpiece.

The fundamental processes, which are carried out in the following order, are constant regardless of the complexity of this methodology:

- The design engineer develops the computer-aided design (CAD) model using relevant software.

- The system receives the design and transforms it into a series of CNC programs.

- This set of computer instructions is used by the CNC machine.

- Using these codes, the CNC machine creates the finished component from the workpiece.

Summing Up!

So, with custom CNC machining, you can handle even the most challenging projects, offering your clients unprecedented flexibility. It’s a beautiful thing!

If you truly want the best bang for your buck, you must ensure that the machining service provider in Houston Texas you choose is right for the job. Be wary of companies offering extremely low prices, since there are always hidden fees or other factors to consider. And never skimp on quality because it could come back to haunt you down the road.

We guess this article has covered a lot of information related to CNC machining. If you want any specific information concerning CNC machining, then leave your comment below in the comments section. Cheers!