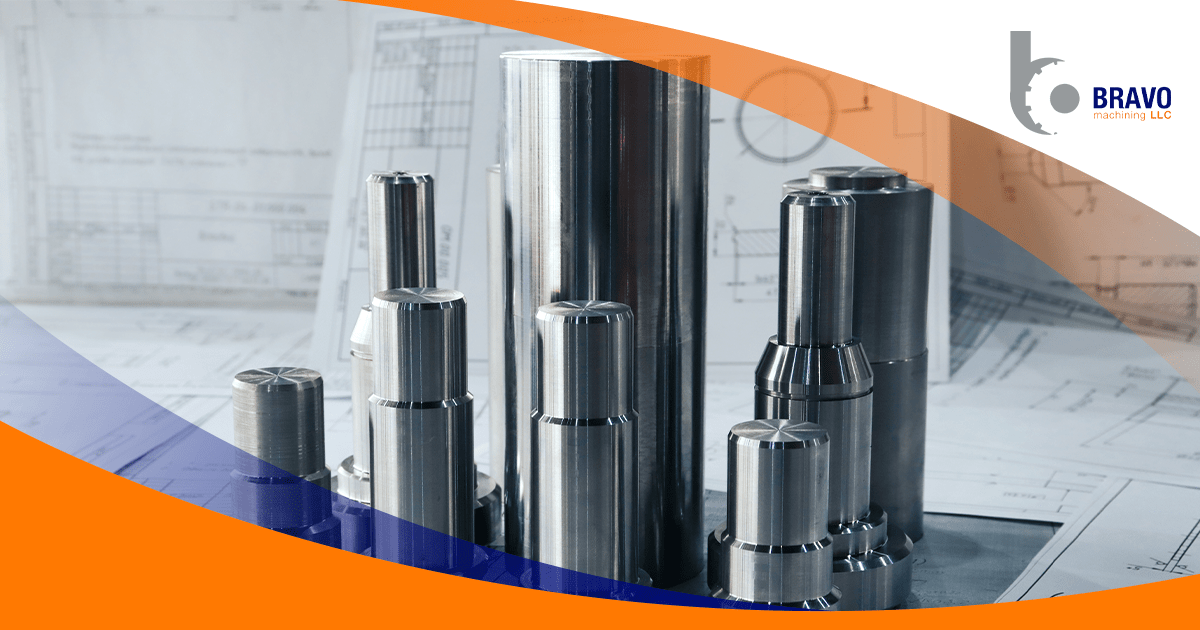

CNC Prototyping is a crucial step in the product development process, allowing designers and engineers to test and refine their ideas before mass production. CNC machining is a popular method for creating prototypes due to its precision, speed, and versatility. In this blog post, we will explore the benefits of CNC machining prototyping and how it contributes to successful product development.

Benefits of CNC Machining for Prototyping:

- High Precision: CNC machining offers exceptional precision, enabling the creation of prototypes with exact dimensions and tight tolerances. This precision ensures that the prototypes accurately represent the final product, allowing for thorough testing and evaluation.

- Quick Turnaround: CNC machining is a fast process, making it ideal for rapid prototyping. This allows designers to quickly produce and test multiple iterations of a prototype, accelerating the product development cycle and reducing time to market.

- Versatility: CNC machines can work with a wide range of materials, including metals, plastics, and composites. This versatility allows for the creation of prototypes that closely mimic the properties of the final product, providing valuable insights during the testing phase.

- Cost-Effective: While initial setup costs for CNC machining can be high, the ability to produce accurate prototypes quickly and efficiently can result in significant cost savings in the long run. By identifying and addressing design flaws early in the process, companies can avoid costly revisions during mass production.

Applications of CNC Machining in Prototyping:

- Functional Prototypes: CNC machining allows for the creation of functional prototypes that can be tested in real-world conditions. This helps identify any performance issues and refine the design before moving to mass production.

- Visual Prototypes: Visual prototypes are used to evaluate the aesthetics and ergonomics of a product. CNC machining can produce high-quality visual prototypes that accurately represent the final product’s appearance and feel.

- Concept Prototypes: Concept prototypes are used to explore different design ideas and concepts. CNC machining enables the quick and precise creation of multiple concept prototypes, facilitating the selection of the best design.

Conclusion: CNC machining is an invaluable tool for prototyping, offering high precision, quick turnaround, and versatility. By enabling the creation of accurate and functional prototypes, CNC machining helps streamline the product development process and ensures the successful launch of new products. As technology advances, the capabilities of CNC machining for prototyping will continue to grow, further enhancing its role in innovation and design.